Assured

responsibility

• 100% of the paper used in

packages is FSC® certified

• 2010: the launch of the Active

Traceability System brings cutting

edge technology to register coded chain information on the package

• 27.1% of post-consumption packages were recycled in Brazil in 2011, representing 59 thousand

tons of material

and Artwork departments

were the highlight in

terms of innovation in the

period.

• PR1 •

Innovation has been part of Tetra Pak's DNA from day one, offering solutions for safety storage of foods, ensuring greater durability and lower production and logistics costs. More recently, the insertion of the Environment strategic pillar marked one more innovation, strengthening the development of recycling and the use of materials from renewable sources.

Innovation is also present in operational management, with regular projects to improve processes and procedures. In 2011, two projects stood out. In the first one, the Logistics Services and Supply department identified recurrent low added value activities by using the Elimate, Combine, Rearrange and Simplify (ECRS) tool. The action plan developed after diagnosing the problem increased in 10.4% the availability of the department for new improvement actions and activities.

The other outstanding project increased the production of Artwork by implementing a new control tool, facilitating the mobility and sharing of digital files from other plants in the group and reducing the time to develop and change packages.

employee

Assured responsibility

• 100% of the paper used in

packages is FSC® certified

• 2010: the launch of the Active Traceability System brings cutting edge technology to register coded chain information on the package

• 27.1% of post-consumption packages

were recycled in Brazil in 2011, representing 59 thousand tons

of material

click

clickto enlarge

Reduction in water consumption in filling machines

Litres/1000 packages

Reduction in energy consumption in filling machines

KW/1000 packages

• EN6 •

EQUIPMENT FOR THE FOOD INDUSTRY

Tetra Pak offers integrated processing, filling and distribution lines, consisting of high-performance, rigorously tested equipment. There are about 90 models of filling and processing machines developed by Tetra Pak in accordance with the specific demands from customers, focusing on food, beverage, milky products, cheese, and ice cream categories.The company's business with equipment goes beyond the development of machines. Tetra Pak provides its clients with consulting to determine the ideal solution for each production line; installs the machinery at the customer's plant; offers traning to employees on the operation of the machines; and provides technical service and maintenance.

PACKAGES

• 2.2 •

Tetra Pak's packages portfolio is wide, offering over 30 thousand packaging possibilities, one for each specific need of the customers. There are 11 types, with volumes varying from 80 millilitres to 2 litres. The combination of different shapes and volumes, together with the different openings, caps and straws, represents a huge portfolio from which the customers can choose the one that better meets their needs. To help them choose, Tetra Pak offers specific consulting, considering issues like logistics, better shelf display, and durability of the food.

Launches

Over the past two years, Tetra Pak has presented innovations in packaging, machinery and services that reflect the use of new technologies for processing systems. The aim is to quickly meet the demands from consumers (for greater functionality) and customers (for portfolio diversification and operating efficiency). The new products reinforce the company's commitment to developing sustainable solutions, ensure higher productivity and deploy cutting edge technology.The Active Traceability System was introduced in the market in 2010. The solution involves the most modern resources in terms of automatized information recording and productive chain control. The system collects data from all manufacturing stages – from receipt of raw material to distribution – and stores it in a code on the package. The data can be stored online for public access.

HOW TRACEABILITY WORKS• PR1 • |

||

|

||

| Every package has a unique product traceability identity code. |

At the manufacture's website the consumer can access a restricted area for queries about the code. |

By entering the code all information about how and where the food was produced is displayed. |

Get to know the packages

Aseptic Packages: they keep food safe and fresh and help keeping its original flavour for at least six months with no refrigeration or preservatives, allowing for the preservation of colour, texture, flavour and nutritional value. They are provided in several shapes: Tetra Brik, Tetra Classic, Tetra Gemina, Tetra Prisma, Tetra Wedge, Tetra Recart and Tetra Evero.

Chilled Packages: they are ideal for products such as pasteurized milk, soy milk and fruit juices. They are provided in the Tetra Rex, Tetra Brik and Tetra Top lines.

Food Packages: the Tetra Recart technology was developed to pack solid foods in several size pieces and it is used today for over 100 products across more than 30 countries. Using this technology, food such as vegetables, beans, grains, soups and sauces can remain at the point-of-sale for up to 24 months because they are sterilized inside the long life package.

Safe packages

Everyone in the food chain is responsible for guaranteeing that only safe products are placed in the market: the raw material producer, the product manufacturer, those in charge of storage and transport, and the supermarkets. And this challenge becomes bigger and bigger because of globalization.

Potential risks of contamination that were once restricted to specific regions of the globe can reach international dimensions these days. Food safety is at greater risk when food is handled, whether during production, filling or distribution. Tetra Pak packages were developed to ensure safety filling and transport of foods.

The aseptic carton package developed by Tetra Pak is produced using high technology and under strict quality standards, which guarantees to customers and consumers food protection and safe distribution of products, regardless of the distances that need to be covered.

In addition, the company has a policy for the identification and registration of products and services that includes the traceability of raw materials. Our major partners, such as Klabin, Braskem, Alcoa and CBA, are publicly renowned for respecting the best environmental practices.

The company also has its own food health and safety policy audited in an annual basis in conformity with the requirements by the US Food and Drug Administration (FDA), and it also follows the European criteria for food health and safety in accordance with the British Retail Consortium (BRC) standards.

THE LAYERS OF THE CARTON PACKAGE

100% recyclable, Tetra Pak's carton packages consist of six layers that protect the food from light, external moisture and microorganisms.

Result: the combination of these layers helps preserve the nutrients, the flavour and freshness of foods for longer periods of time, at the same time it saves energy because it needs no refrigeration before being opened.

The intelligent shapes of the packages make them easier to be carried, handled and stored and provide them with higher strength to falls.

Result: lower logistics and storage costs and reduced losses when handling the products.

Responsibility for the products

• EN26 •

Tetra Pak's plants in Monte Mor (SP) and Ponta Grossa (PR) adopt the Integrated Management System (IMS) and they are both certified ISO 9001, ISO 14001, OHSAS 18001 and Food and Drug Administration (FDA) standards, and they are annually audited as a way of showing the company's commitment to quality, the environment, health and safety of the employees as well as food safety.

Storage and distribution of products and services follow internal standards which are in line with the market's best practices. The products are regularly assessed to ensure their applicability and approved in markets where health and safety are highly demanded, such as in Europe and the US, and they also fully meet the needs of the Brazilian market.

Tetra Pak Brasil also submits the packages to assessment by the Brazilian Health Surveillance Agency (Anvisa). In 2011, Total Migration and Specific Migration tests were carried out in conformity with resolutions RDC 51 and RDC 52 by Anvisa at the ITAL-CETEA laboratory. All products assessed passed the tests.

| Year of certification | ||

|---|---|---|

| Ponta Grossa | Monte Mor | |

| ISO 9001 | 2002 | 1996 |

| ISO 14001 | 2002 | 1997 |

| OHSAS 18001 | 2007 | 2007 |

| FDA | 2011 | 2011 |

Post-consumption responsibility

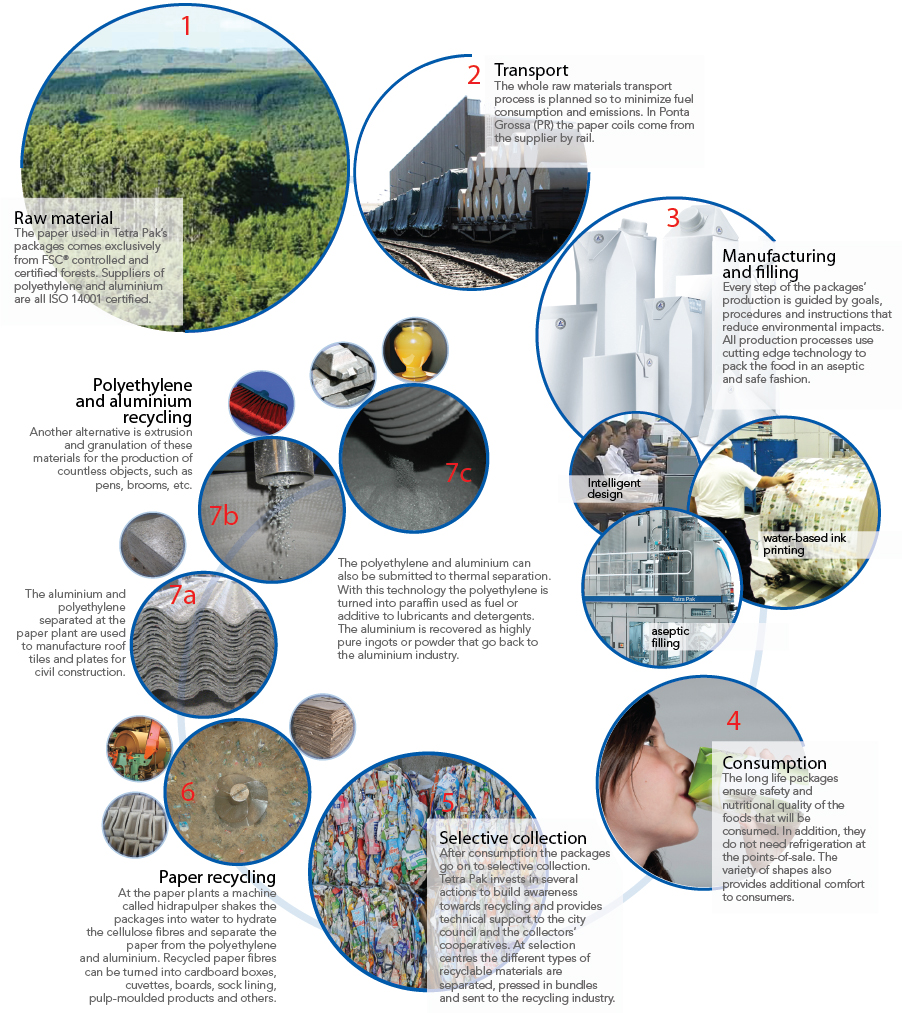

Paper is the major raw material in long life packages, representing 75% of its total weight, followed by 20% low density polyethylene and 5% aluminium. Tetra Pak is aware of its responsibility for the reverse logistics of the products traded and, therefore, the company acts as a catalyser for the recycling chain all over the country, promoting the development of new technologies and recycled products, the increase in recycling installed capacity and the training of collectors' cooperatives. It all aims at making the recycling chain more sustainable and immune to market oscillations, as it happened during the economic meltdown in 2008-2009, when the price of recycled materials plunged, thus reducing the recycling rates.

Tetra Pak's packages are 100% recyclable. The company also invests in environmental education and awareness and provides technical support to stimulate recycling; through the Brazilian Business Commitment to Recycling (Cempre) Tetra Pak participated in the creation of the new National Policy on Solid Waste, recently approved of by the Brazilian Congress. These sorts of efforts have proven to be effective. After dropping to 22% during the financial crisis in 2008-2009, Tetra Pak's packages recycling rates recovered in 2010 reaching the historical mark of 24.5%, and 27.1% in 2011, which represents 59 thousand tons of post-consumption recycling.

Post-consumption packages recycling rates

• EN27 •

TETRA PAK'S PACKAGE LIFE CYCLE

Recycling

Technologies and partnershipsTetra Pak has developed one more method to recycle long life packages, turning them into pulp-moulded parts. The material replaces expanded polystyrene wedges (an oil sub-product) used for the transport and protection of electronic equipment, in cuvettes for seedling, etc.

There are three different processes to recycle polyethylene and aluminium: one of the choices is the manufacturing of roof tiles and boards by hot pressing the material. In 2010, Tetra Pak prepared, in association with the Brazilian Association of Technical Standards (ABNT), a voluntary certification for the roof tiles made out of the polyethylene and aluminium recovered from long life packages to ensure the quality and reliability of the product. A pilot project has been carried out at one plant that shall get the certification in 2012.

Another alternative is the production of polyethylene and aluminium pellets for the production of several objects such as pens, notebook covers, folders, removable flooring, waste baskets and others. The third process was developed in 2005 by Tetra Pak, in association with companies such as Klabin, Alcoa and TSL Environmental, and allowed for the full separation of the polyethylene and aluminium layers using thermal separation technology. The outcome of this process is aluminium ingots or powder (used for the production of metal paints or parts for the casting industry) and paraffin (used in the production of waterproofing materials and lubricants or as a raw material for the chemical industry).

In 2010 and 2011, Tetra Pak kept partnerships with 31 post-consumption long life packages recycling plants in Brazil in the following states: Bahia, Espírito Santo, Mato Grosso, Minas Gerais, Paraná, Pernambuco, Rio Grande do Sul, Santa Catarina and São Paulo.

An example of such partnerships was the implementation of a recycling plant for the separation of paper pulp from the post-consumption package and further sale to paper plants, added by the manufacturing of roof tiles and boards with the remaining polyethylene and aluminium. Supporting the recycling industry in the North-eastern region, Tetra Pak promoted a new business model in the region.

Another important partnership regarding the development of technologies took place at a recycling plant in the State of Santa Catarina that produces boards for sock lining and notebook covers, which require high-resistant long paper fibres. After the first contact and some developments, in 2010 the long life packages started being used as raw material.

With Tetra Pak's support, the recycler will soon see its installed capacity increase from the current 300 tons to about 1,000 tons of long life packages per month.

Encouraging selective collectionThe work developed at the cooperatives is a crucial social pillar supported by Tetra Pak, because especially in developing countries, the waste collector's activity is closely linked to social needs. By acting together with Cempre, the company encourages that collectors work in cooperatives and manage their organizations in a professional fashion, aiming at better conditions and business opportunities, strengthening its role as a provider of recyclable materials to the recycling industry. This is done by training collectors' cooperatives, besides providing assessment and technical information related to the economic and environmental aspects of the activity, added value to products, and shared technologies.

Tetra Pak also furnishes materials to City Councils, supermarkets and other organizations to create Voluntary Delivery Points (VDPs). By establishing partnerships with customers and retailers there are now 240 VDPs supported by the company. The company provides a search tool to locate these recyclables' collection points on the website www.rotadareciclagem.com.br.

| Statistics of the Recycling Route website | ||

|---|---|---|

| Index | 2010 | 2011 |

| Visits | 116,165 | 166,622 |

| Page views | 409,916 | 513,010 |

| New visits (%) | 84.93 | 82.99 |

To nourish the chain and promote new recycling businesses, Tetra Pak Brasil has a field team that visits collective selection initiatives (recycling cooperatives, chips and scraps plants, voluntary delivery points, etc.) to monitor the development of the sector by mapping the regions to identify needs and opportunities. People allocated in several municipalities in the country coordinate the local mapping activities.

These groups spread information about equipment, added value and productivity. In 2010, 2,177 entities were mapped, out of which 1,686 received long life packages. In 2011, the mapping reached 3,201 entities, out of which 1,804 accepted the package.

NATIONAL POLICY ON SOLID WASTE

First company in the packaging sector to be ISO 14001 certified, Tetra Pak Brasil has long been promoting the best environmental practices; it has also participated in the movement that led to the consolidation of the National Policy on Solid Waste enacted by the Brazilian President in August 2010. The company participated in that process through the Brazilian Business Commitment to Recycling (Cempre), a not for profit association dedicated to the promotion of recycling within the waste integrated management concept. Founded in 1992, the organization is kept by private companies from several sectors, including Tetra Pak Brasil.

Together with LIDE Sustainability, a group of business leaders, and the SOS Mata Atlântica NGO, Cempre activity was an example of how the chain manages to get together and transform the public policy. The National Policy on Solid Waste brings innovations such as shared responsibility between the chain, the public and private sectors and the society, besides proposing the reverse logistics of several materials, such as batteries, tires, electronic equipment and others.