Sustainability Report

Network-enterprise

Algar Agro adopts the Integrated Management System (IMS) to perform on the world soybean supply chain, increasing efficiency of the systems that manage quality, environment and health and safety, and seeking to attend to the specific needs of its clients as well as the expectations of suppliers, associates and shareholders.The base for management decisions is the integration of all data and processes of the organization in an own model called network-enterprise, which is also utlilized by other Grupo Algar companies.

In this model the Company is structured into small internal units called Results Centers. With their own targets and budgets, each one of these centers contributes to the development of the strategic plan of the Company. The Executive Board aligns them to the objectives established by the Board of Directors.

For the concept of network-enterprise to work the corporate culture has to be democratic, where all are prepared to give suggestions, listen to criticisms and, principally, learn. The main characteristic of the model is participatory management – the process stimulates commitment and autonomy with responsibility, allowing each associate, independently of hyerarchical level, to participate in the decisions that affect the sustainable future of the company.

Business Segmentation

Origination, crushing, refining and distribution of soybeans

Algar Agro is established as a large scale player in the soybean market, with a vertical business strategy that encompasses soybean origination, crushing, refining and packaging, production of soybean meal and marketing of soybeans and derivatives.

The origination of grains is done through direct purchases from individual producers. Grupo Algar cultivates close relationships with their different stakeholders – this provides competitive advantage in terms of origination, since there is very low turnover amongst field agents who are responsible for attending to the soybean producers. This allows Algar Agroto establish long term relations with producers, getting to know them, participating actively in the whole process and accompanying all stages of the harvest.

Strategically placed throughout the main soybean producing regions, (Minas Gerais, Goiás, Mato Grosso, Maranhão, Piauí, Tocantins and Pará), Algar Agro’s soybean buyers are always ready to help the producers in all their needs. Support may include technical help for planting or preparing the necessary paperwork and documents for raising bank loans. Algar Agro is a manager of solutions, leaving producers to concentrate on their core business, which is to grow soybeans.

Another advantage much valued by producers, which has helped to strengthen the relationship, is the fact the Algar Agro is a Brazilian company, also an agricultural producer, financially solid with a well recognized operational efficiency. Such attributes helped the company to originate more than 1.3 million tons of soybean in 2011, representing an increase of 14% in relation to the previous year. Of this, 50% was exported, mostly to Europe and Asia, in grain or meal formo.

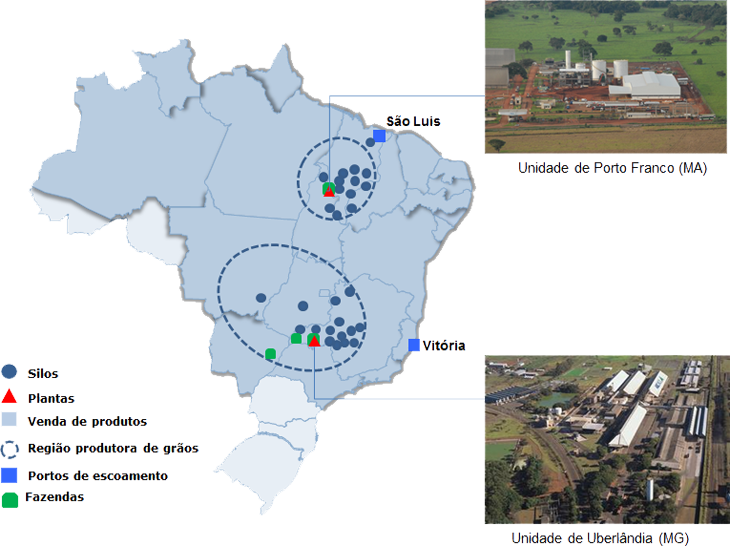

In order to store the soybean at harvest time, Algar Agro counts with 28 warehouses spread throughout the States of Minas Gerais, Mato Grosso, Goias and in the MAPITOPA region, with a storage capacity of 1 million tons of beans.

The processing of the soybeans is done in two strategically placed units. With an area of 406 thousand sqm, the Uberlândia/MG unit is one of the most advanced industrial complexes for soybean crushing and refining in the country. It has a storing capacity for 180 thousand tons of beans and can crush 1800 tons of soybean daily – in 2011 it crushed 545 thousand tons. Equally equipped with cutting-edge technology is the unit of Porto Franco, in the State of Maranhão, which occupies an area of 200 thousand sqm and can store 60 thousand tons and crush 1600 tons daily. In 2011 it crushed a total volume of 188 thousand tons.

RaçaFort Soybean meal

A component in the rations for a diverse group of animals (fish, goats, sheep, cattle, horse, pigs, poultry and others) RaçaFort Soybean Meal’s main clients are the companies that produce animal protein in Brazil. It is sold in 60 kilo bags and in bulk. Internationally, the product has been awarded certification PDV: GMP+B2 in conformity with the standards of the GMP+ International organization, which establishes a model of conduct and procedures to assure the safety of components of animal feed, and of the animals that feed on it.

During 2011, Algar Agro sold 574 tousand tons of soybean meal of which 424 thousand tons from the Uberlândia unit and the rest from the Porto Franco unit. Of these, 150 thousand tons were destined for export, maintly to countries of Europe such as Portugal, Holland and Spain, and to Latin America, generating sales of around US$57 million.

ABC de Minas range of food productss

Produced since 1989, Algar Agro soybean oil has been the market leader in the state of Minas Gerais for the past five years. In the past year, production has totalled 6.5 million boxes and the market share in Minas Gerais, where 80% of production is sold, was 28% at year-end. The rest of production is sold in the Southeast region, in cities near the state of Minas Gerais, as well as in ten cities of the Northeast region.

Originally labelled ABC, the Company’s brand of soybean oil was subject of a study in 2008 when it was established that, as well as having the same quality as the top players, the product attracted the local consumers for being seen as a local product. To reinforce this identification, the brand was renamed ABC de Minas, and included another four products made by external partners. As well as the soybean oil, the product range now includes extra virgin olive oil, vegetable oil and tomato sauce and paste.

Agriculture and Cattle Farming

Algar Agro owns more than 9800 hectares of plantation of which almost 80%, or 7500 hectares, are for cultivation of soybean in farms located in the Triângulo Mineiro Region. The area under irrigation, which is projected to increase in the next years, corresponds to 7%.

The production of soybean is absorbed almost totally by the processing plant in Uberlândia. A small fraction of around 5% goes to a seed processing plant, also in Uberlândia. Maize, for sale in the domestic market, occupies the other 20% of planted area.

In the farms of the Triângulo Mineiro Region there is also a dairy herd numbering around 1200, which produced almost 2.5 million liters in 2011. Algar Agro’s beef cattle herd is situated in a farm located in Paranaíba, State of Mato Grosso do Sul. There are 6500 hectares of pasture with a herd that numbered, at the end of 2011, 10.6 thousand head of cattle. The activities of breeding and fattening are geared to the domestic market.

Growth Strategies

(IMAGEM SEM TRADUÇÃO!!)

The location ot Algar Agro’s fixed assets is one of the pillars of the Company’s growth strategy. The Uberlândia unit offers easy access to the soybean producing regions of the States of Minas Gerais, Mato Grosso and Goiás and contributes to a competitive logistic system towards the export markets through the ports of Tubarão (ES) and Santos (SP). Furthermore, the Triângulo Mineiro Region has skilled labour and offers easy access to the main consuming centers of Brazil, being close to the geographic center of the country, being a region of junction of different railways, and located in the heart of the Southeastern Region, which concentrates 56% of Brazilian GDP.

In the same way, the Porto Franco unit in the state of Maranhão is located near the soybean producers of the MAPITOPA and channels production to the export markets, via the Terminal Marítimo de Ponta da Madeira (MA). The warehouses are also strategically located, near to the producing regions, in the vicinity of processing plants and producers.

Logistics has a large impact on the distribution routes and, consequently, on the final cost of the soya-based products, where the transportation costs play a significant part. In the case of the soybean oil ABC de Minas, where the quality of the competing products is high, the purchasing decision is taken at the moment of purchase and according to the shelf price, having a low cost base makes all the difference.

In 2012 a new refining and packaging plant will be inaugurated at the Porto Franco unit in Maranhão, which will expand the consumer market for the Company’s soybean oil, increasing penetration in the North and Northeastern regions of the country. At present, the region receives about 10% of the Minas Gerais production. With the new plant, which is due to open in the first half of 2012, the Company will have the potential to market another 5 million boxes of soybean oil per annum.

In parallel with the construction of the new refining and packaging plant, built with an investment of R$50 million (R$23 million invested in 2011 and the rest in 2012), the Company’s marketing area has devised a campaign which will focus initially on 10 states of the North and Northeastern regions. As is the case in the Triângulo Mineiro and adjacent regions, the marketing plan for the ABC de Minas range is based on Algar Agro’s marketing management model, which seeks partnership with clients and suppliers as well as identifying consumers. In other words, it is a high quality product which is priced competitively and, though it carries the ABC de Minas brand, it is locally made, using local labour and services.

Another pillar of the sales strategy is to focus on smaller clients. Instead of dealing with the large supermarket chains, whose buying power squeezes the margins of suppliers, Algar Agro’s products are sold in small to medium sized shops, with which the Company’s consultants cultivate long term relationships.

Risk Management

In line with best corporate governance practice, Algar Agro counts with Grupo Algar’s Audit and Risk Management Committee, which reports to the Board of Directors, to identify, evaluate and classify the risks which are inherent to the Company’s activities; and devise action plans to deal with them.During 2011, Algar Agro’s activities in the area consisted in mapping out and monitoring the strategic, operational and financial risks of the business, from agricultural production up to the product sale. As well as the direct business risks, other risks were analysed, such as those linked to the entities Algar Agro and Grupo Algar, like the risk of image damage. The analysis resulted in pinpointing fifteen risks which had already been identified within the business. During 2012 risk management will focus on mitigating the risks already identified.

The model used is based on the Enterprise Risk Management (ERM) methodology adopted by the Committee of Sponsoring Organizations (COSO) an international organization dedicated to the establishment and dissemination of best practice in risk management, internal controls and fraud detection. top