Operating performance

Tractebel Energia believes the reliability, uptime and safety of its generator complex are fundamental aspects in quality management. The Company measures these aspects through an internal plant uptime indicator, the calculation of which takes into account the energy supply capacity of the installations and the period of unscheduled and emergency downtime at the generator units.

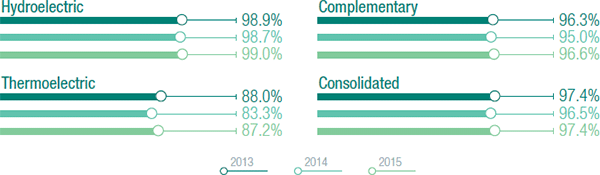

For the full 12-month period of 2015, excluding scheduled stoppages, the plants reported uptime of 97.4%: 99.0% in the case of the hydroelectric plants, 87.2% for the thermal powered units and 96.6% for the units driven by complementary sources.

Plant uptime, excluding scheduled stoppages

The overall uptime for the year taking into consideration programmed stoppages was 86.9%: 89.1% for the hydroelectric plants, 72.5% for the thermoelectric plants and 87.2% for the plants powered from complementary energy sources. Modernization work in progress simultaneously at the Salto Santiago and Passo Fundo power plants and programed modernization at Ponte de Pedra, depressed the overall uptime performance of the hydroelectric plants and reflected in the overall uptime result as well.

The following table shows the corporate targets for the principal operating indicators and the results achieved in 2015 for the management of plant operational quality.

| Description | Target | Result |

|---|---|---|

| Uptime at the hydroelectric plants, discounting programmed stoppages | 98.5% | 99.0% |

| Satisfaction Ratio of the National Electric System Operator (ONS) | 90.0% | 93.6% |

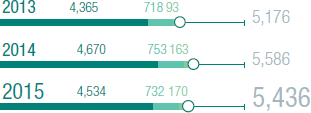

In 2015, the Company’s total electricity energy output reached 47,622 GWh (5,436 average MW): a reduction of 2.7% in relation to 2014. This is is is due above all to low flow hydrology in the North Region, the location of the Estreito and Cana Brava hydro plants, and to the programmed stoppages for modernization of the generator units units at the Salto Santiago, Passo Fundo and Ponte de Pedra operations. Out of total generated energy, the hydroelectric plants were responsible for 39,723 GWh (4,534 average MW), a 2.9% reduction; the thermal plants, for 6,410 GWh (732 average MW), a decline of 2.8%; and the complementary plants for 1,489 GWh (170 average MW), an increase of 4.0%.

In this context, it is worth pointing out that an increase in the Company’s hydroelectric generation does not necessarily reflect an improvement in economic-financial performance. Conversely, a reduction in this type of generation does not imply categorically a deterioration in economic-financial performance due to the adoption of the Energy Reallocation Mechanism (MRE), which defrays the risks of hydro generation among its participants.

As to the Company’s thermal generation, its increase reduces exposure to the Price for the Settlement of Differences (PLD), the opposite being the case when there is a decrease, all other variables being equal.

With its coal-fired thermal plants, Tractebel Energia has set a priority to achieve reference values for net energy efficiency as established in Aneel’s Normative Resolution 500 of July 17, 2012. This establishes an efficiency value of 25% for plants with an installed capacity of up to 50MW; 30% above 50MW and up to 150MW; and 35% for remaining plants. GRI G4-EU11

Generation (in average MW)

| Thermoelectric Plants /Unit | Installed capacity (MW) | Average efficiency (%) | Main fuel | Aneel reference value (NR 500)1 | |

|---|---|---|---|---|---|

| Jorge Lacerda Complex | UTLA 12 | 100 | 22 | Coal | 30 |

| UTLA 22 | 132 | 29 | Coal | 30 | |

| UTLB | 262 | 29 | Coal | 35 | |

| UTLC | 363 | 34 | Coal | 35 | |

| Total CTJL3 | 857 | 31 | Coal | 33.65 | |

| Charqueadas | UTCH | 72 | 19 | Coal | 25 |

| William Arjona | UTWA | 190 | 26 | Gas | - |

| 1.The reference values in Aneel’s Normative Resolution 500 relates to coal-fired thermoelectric plants only. 2. The UTLA units were listed individually (in 1 and 2) given their differing characteristics (in terms of operating periods, equipment manfacturer, installed capacity etc.). 3. In the case of the thermoelectric complexes where there is more than one plant belonging to the same concessionaire, the use of the reference value for measuring net energy efficiency may be on a joint basis. |

|||||