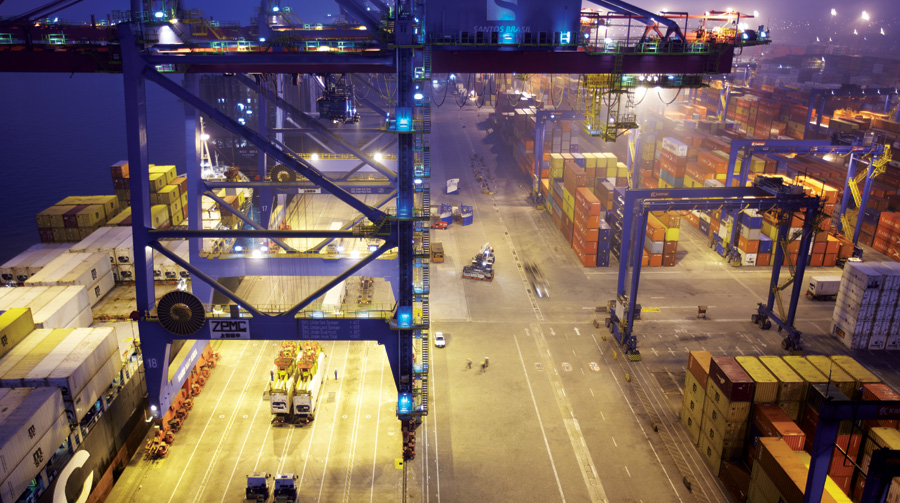

TECON SANTOS

Benchmark in modernity in South America, Tecon Santos is the largest and most efficient container terminal in the country. Located on the left bank of the Port of Santos, it was inaugurated in August 1981 and initially managed by Portobras and subsequently by the São Paulo State Dock Company – CODESP until November 1997 – when Santos Brasil won the bid for a 25-year port services concession, renewable for a further 25 years.

With an annual handling capacity of 2 million TEU (unit equivalent to a 20-ft. container), Tecon Santos occupies a total area of 596,000 square meters, with 980 meters of its own docking quay formed by three mooring berths in addition to a fourth berth of 310 meters at adjacent public quay that may be used for both vehicles vessel and container vessel operations.

SHIP-TO-SHORE CRANES.

In order to achieve and maintain these productivity and excellence levels in terminal operations, in addition to its highly trained team, Santos Brasil combines state-of-the-art information technology with the latest-generation equipment. The Company was a pioneer in the introduction of Double Hoist quay cranes in Brazil, considered the most modern on the world market. The six cranes used by Tecon Santos are the only ones in operation in the Americas and handle up to two full 40-ft. or four 20-ft. containers – double the capacity of other cranes – simultaneously. This equipment operates up to the 21st container row, common in vessels that ship up to 13,000 TEU and that are expected as soon as dredging of the deepening of the Port of Santos channel is completed.

Pioneer in the application of new technologies, Tecon Santos uses modern container-positioning systems via GPS; one of the most advanced port software applications in the world, the Navis yard manager, which provides greater operating efficiency; and the OCR (Optical Character Recognition) technology, ensuring absolute control over the entry/exit of trucks at the terminal.

During the year, a new cargo weighing system, developed by Santos Brasil in a partnership with the systems provider, was installed in the yard cranes RTG (Rubber Tyred Gantry Cranes). Container weighing, which was previously done only on conventional scales, is now also performed by the same equipment that moves the cargo, eliminating a phase in the operation and thus reducing handling time. With the implementation of the weighing system also in the RTG, the terminal ended 2011 with a total of 15 import container weighing scales in the RTG in addition to the four conventional scales that already existed.

Tecon Santos occupies a 596,000 sqm site and has 1,290 meters of available quay

.

Another important investment made this year towards greater productivity was the acquisition of 30 Terminal Tractors, Internal handling equipment that pulls trailers with the capacity to transport up to two 40-ft. containers or four 20-ft. containers simultaneously. The new equipment, designed exclusively for internal container handling operations, is part of a fleet that also includes 78 units which are to be gradually replaced by the new models, and have replaced the same number of conventional trucks.

To optimize storage space and at the same time increase the operating capacity of Tecon Santos, 12 RTG (cranes on tires) that perform container handling in the yards, have also been purchased – three of them already began operations in 2011. In total, the terminal has 46 RTG, of which 34 were already functioning. The new Twin Pick model equipment handles two 20-ft. containers simultaneously, enabling faster and more precise maneuvers due to their increased stacking capacity, providing increased productivity as well as a reduction in fuel consumption, which contributes to a reduction of CO2 emissions in the atmosphere.

The extended use of RTG to maneuver and handle containers instead of Reach Stackers forklifts, which consume more fuel, was one of the main contributing reasons to the terminal's evolution in relation to the environmental issue, with a reduction in CO2 emissions in the atmosphere. The Inventory of Greenhouse Gas Emissions (GGE) completed in October 2011 pointed to a 13.63% reduction in CO2 emissions (2010 vs. 2009). For the coming years the Company is studying the possibility of using electrically-powered equipment instead of diesel-powered equipment and the use of less polluting fuels such as Natural Gas and biodiesel in its truck fleet.

EVOLUTION IN HANDLED CONTAINER VOLUME IN THE PORT OF SANTOS AND TECON SANTOS – TEU MILLION

SHARE OF THE PORT OF SANTOS IN FULL CONTAINER HANDLING IN BRAZIL.